"Why Servo Stabilizers & Isolation Transformers Matter"

Protect your equipment from voltage fluctuations, power surges, and electrical noise. Servo voltage stabilizers ensure stable power supply, while isolation transformers provide safety and clean energy. Ideal for industries, hospitals, labs, data centers, and sensitive electronics

Oil-Cooled Servo Stabilizers

Efficiently manage heavy load fluctuations with our oil-cooled servo voltage stabilizers. Designed for industrial applications, they offer high performance, thermal stability, and long operational life. Ideal for factories, CNC machines, printing units, and manufacturing plants, ensuring uninterrupted and safe power supply even in harsh environments.

Air-Cooled Servo Stabilizers

Ensure reliable power with our air-cooled servo voltage stabilizers, ideal for commercial setups, laboratories, offices, and IT environments. Compact, efficient, and low-maintenance, they protect sensitive equipment from voltage fluctuations, ensuring consistent performance and energy efficiency.

Power Conditioner

Designed for precision and protection, our power conditioner servo stabilizers not only regulate voltage but also filter electrical noise, suppress spikes, and ensure clean power delivery. Ideal for medical equipment, laboratories, IT systems, and other sensitive electronic devices, they help extend equipment life and maintain consistent performance.

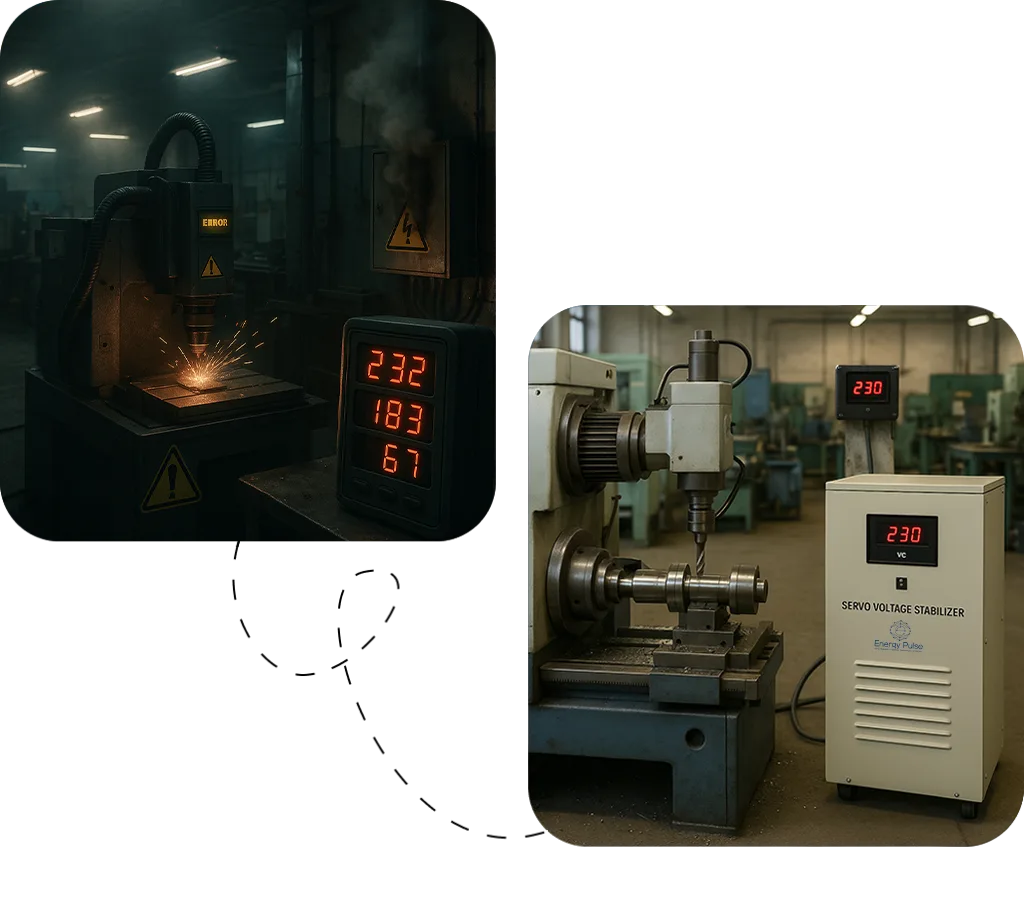

why you need servo stabilizer ?

Servo voltage stabilizers protect your electrical equipment from voltage fluctuations by maintaining a constant output voltage. They ensure smooth operation of sensitive machinery, reduce the risk of damage, prevent downtime, and extend the lifespan of industrial and home appliances. Ideal for factories, data centers, hospitals, and homes, servo stabilizers provide reliable voltage regulation for uninterrupted performance.

Custom-Built Servo Stabilizers & Isolation Transformers Tailored to Your Power Needs

We design and manufacture custom servo voltage stabilizers and isolation transformers to match your exact electrical requirements.

Why Choose Stabilizers & Transformers?

Servo Stabilizer Benefits:

- Protects equipment from voltage fluctuations

- Improves machinery life and performance

- Ideal for CNC machines, medical equipment, etc.

Isolation Transformer Benefits:

- Electrical isolation for sensitive devices

- Noise reduction and spike protection

- Used in labs, hospitals, and telecom sectors

How a Servo Stabilizer is Made in our Manufacturing Unit

At Sri Mahasvin Servomax Industries Pvt Ltd (Energy Pulse), we manufacture high-quality servo voltage stabilizers using a fully in-house, ISO certified process. Each unit is custom-designed based on the client’s voltage requirements, phase type, and load capacity (ranging from 1 kVA to 2000 kVA).

The production process begins with the selection of premium CRGO or EI cores. Precision copper coil winding ensures efficiency and low heat loss. Our team assembles the buck-boost transformer, varnished and heat-treated for durability. A robust servo motor with a carbon brush system is mounted to adjust voltage in real-time via the autotransformer winding.

We integrate a microcontroller-based control PCB that continuously monitors input voltage and ensures precise correction, while also providing protections like overload, short-circuit, and under-voltage cutoffs.

The entire system is enclosed in a laser-cut, powder-coated steel cabinet that resists corrosion and ensures long-term use. Each stabilizer undergoes rigorous load testing, voltage fluctuation simulation, and safety checks before packaging and dispatch.

Our stabilizers are trusted across industries including CNC machinery, hospitals, telecom, labs, houses, and data centers. We focus on reliability, energy efficiency, and long-term performance.